Engineering DFM / Analysis

We provide engineering analysis for your design, applying scientific analytic principles and processes to uncover the properties and state of your system, device, or mechanism under study.

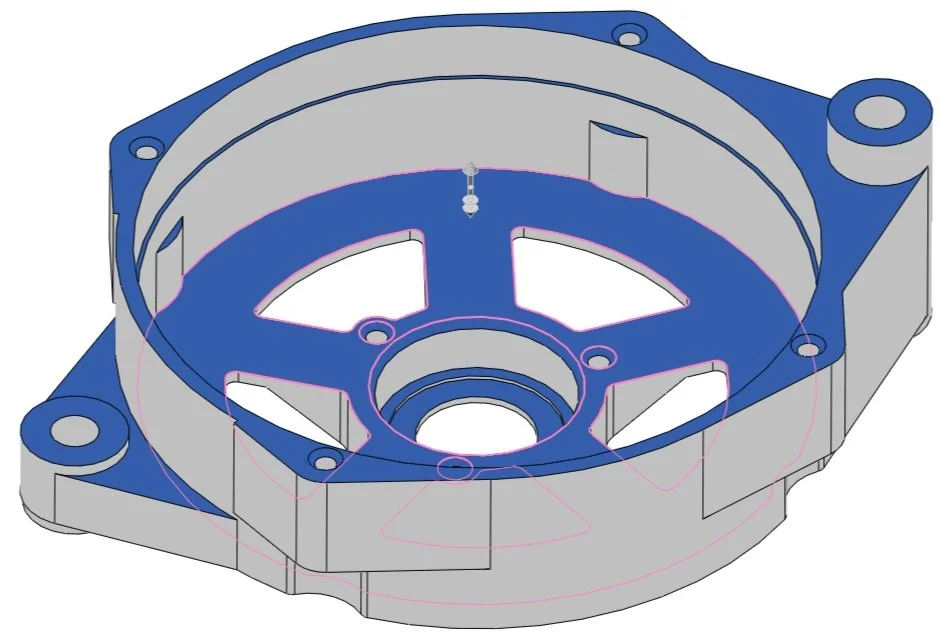

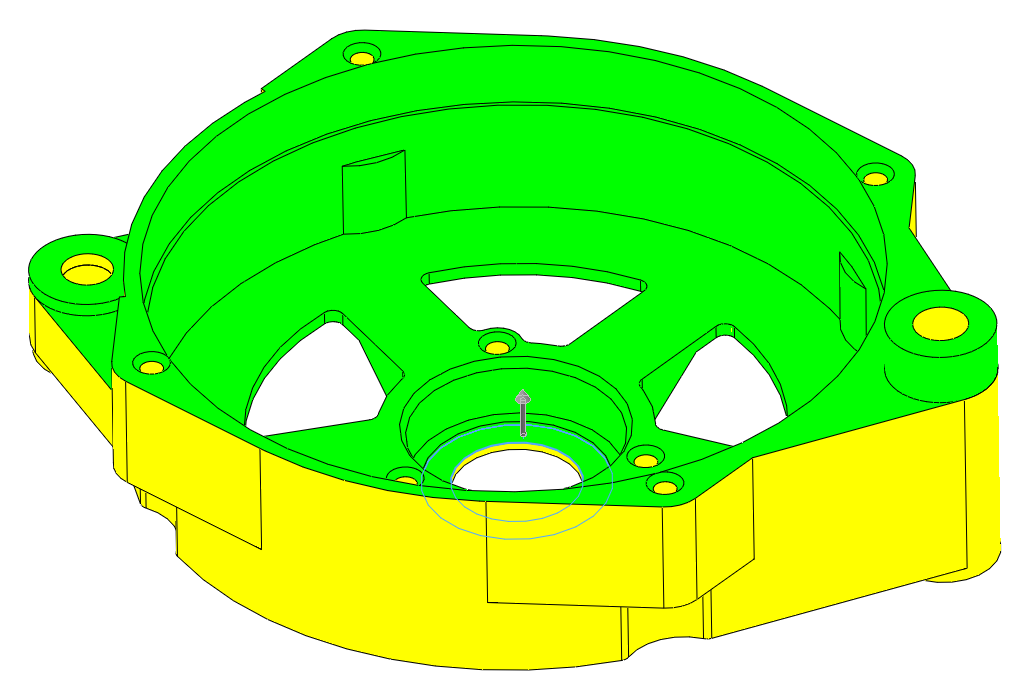

Design For Manufacturing with draft and thickness analysis

Part expectancy with Fatigue and Finite Element Analysis

Ask about our access to Mold Flow Analysis for injection molding

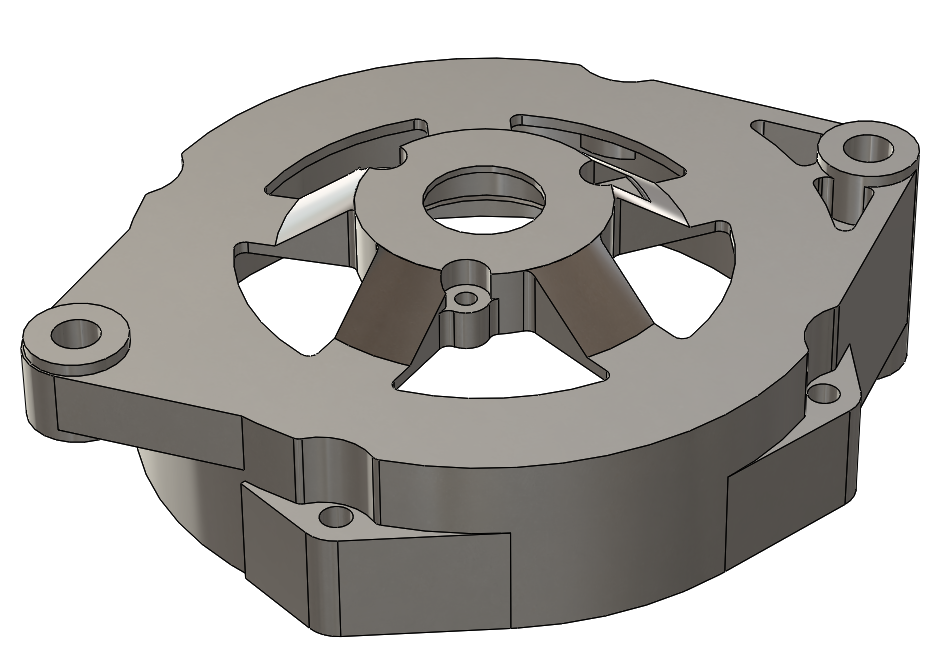

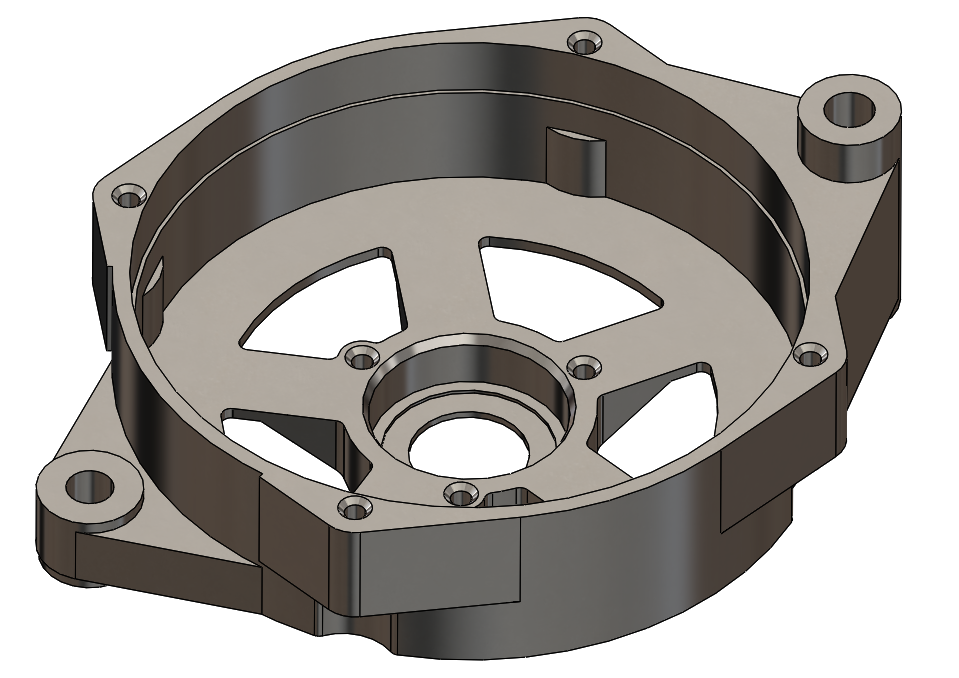

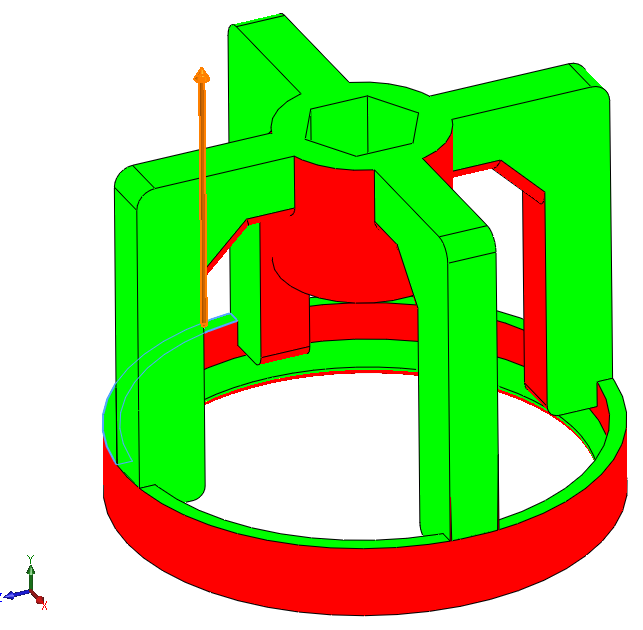

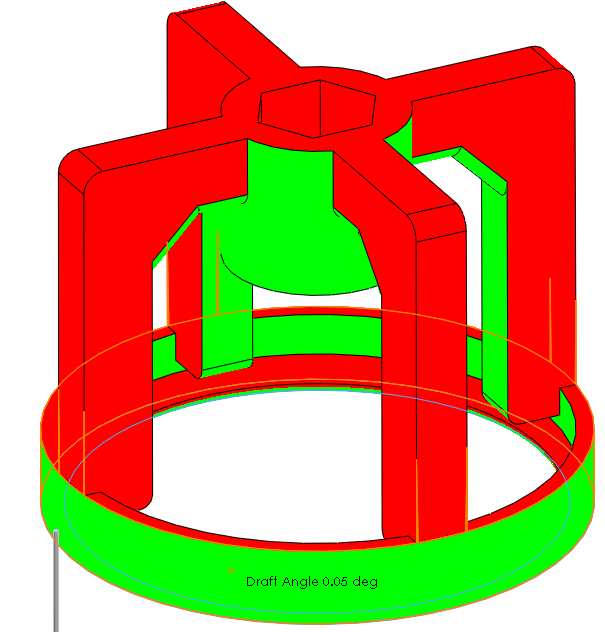

Designed alternator housing for metal casting production. Design for manufacturing was performed, analyzed and implemented part thickness, undercuts, and draft angles.

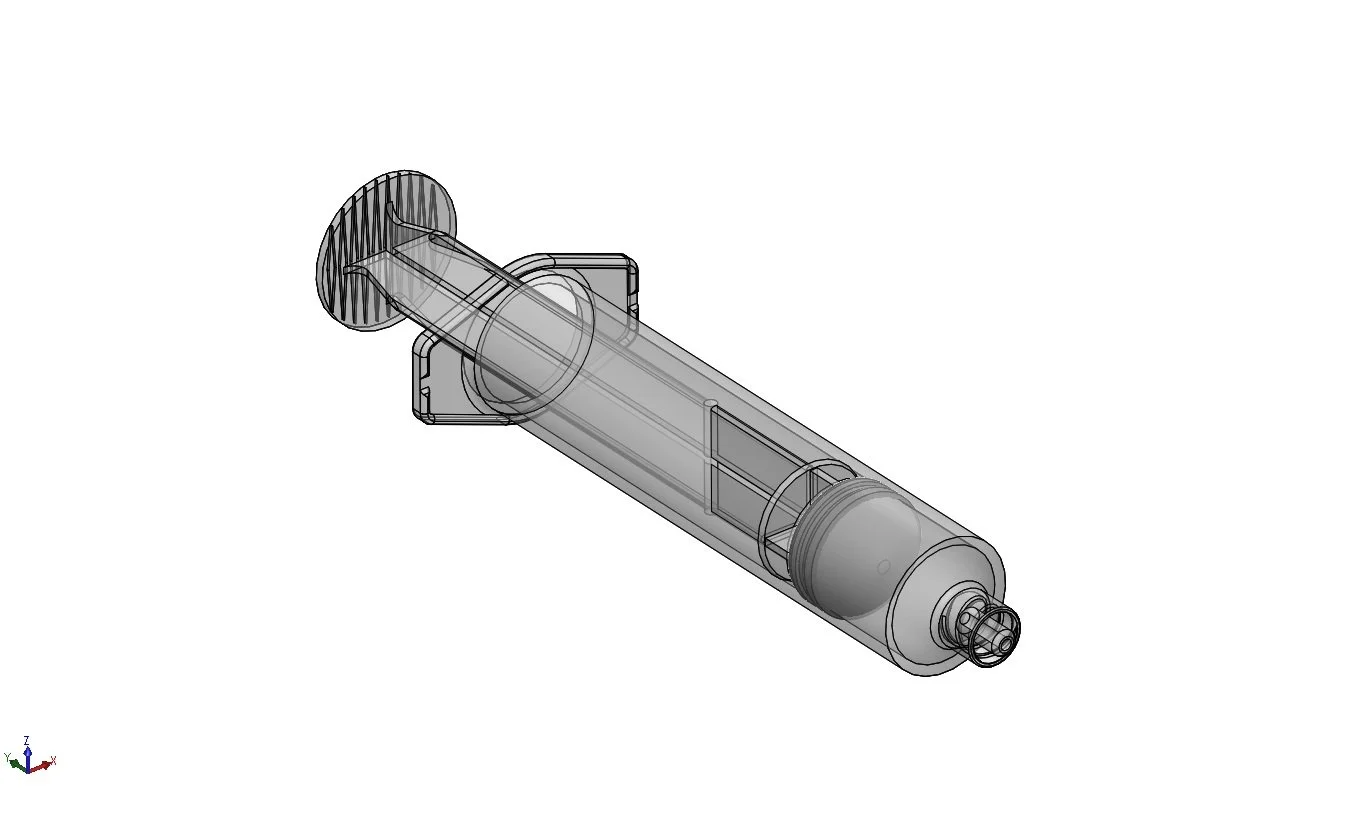

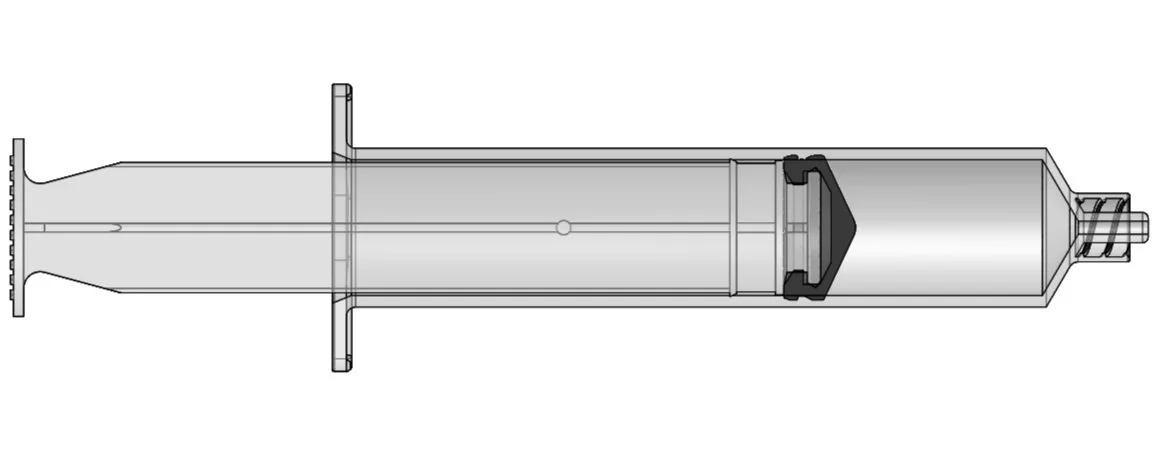

Custom plunger to meet specific crush requirements, suitable for injection molding.

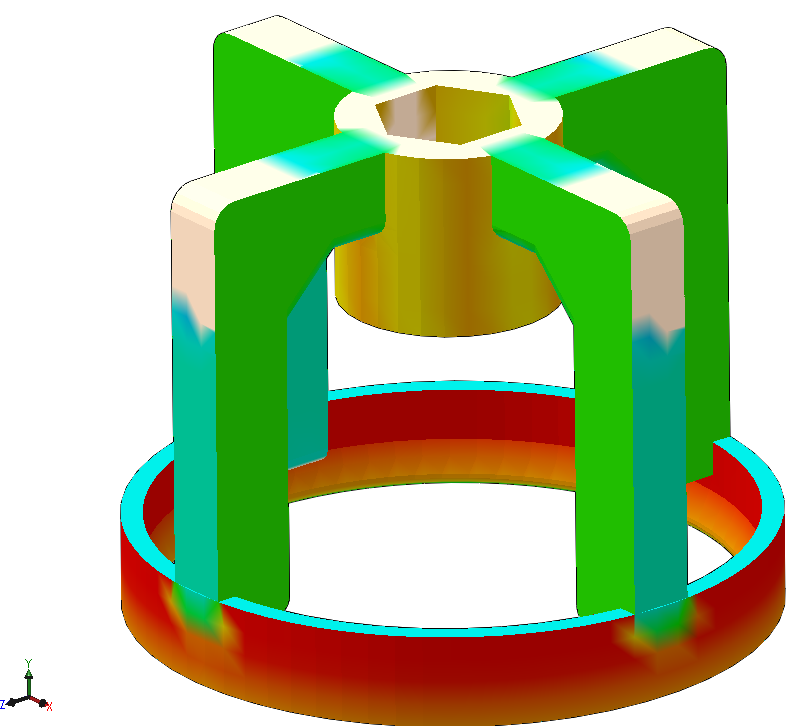

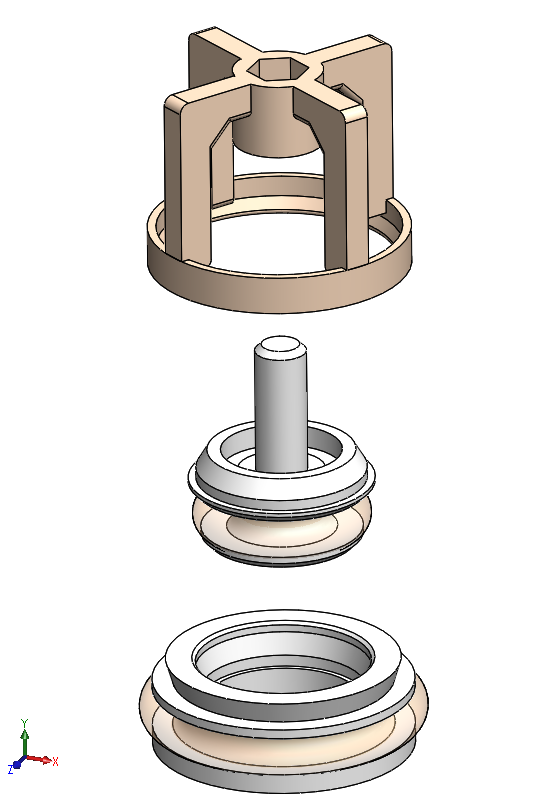

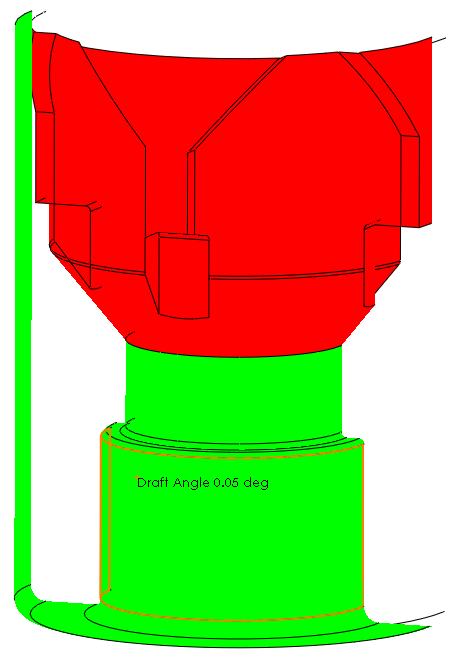

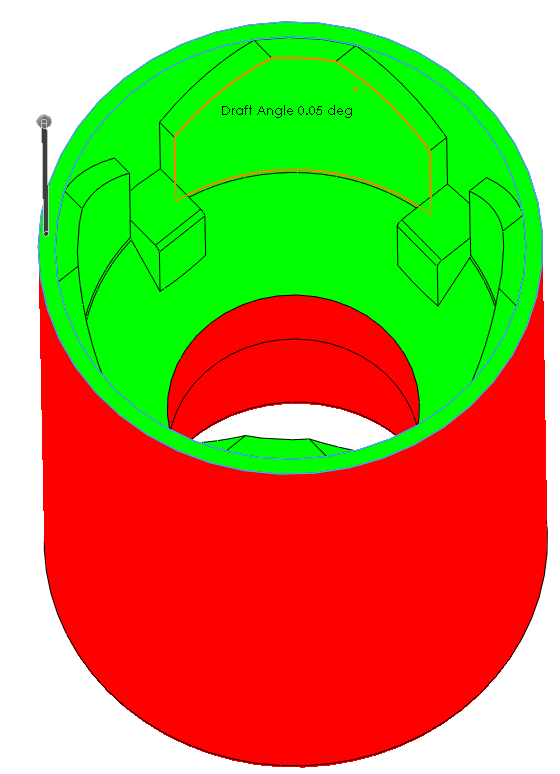

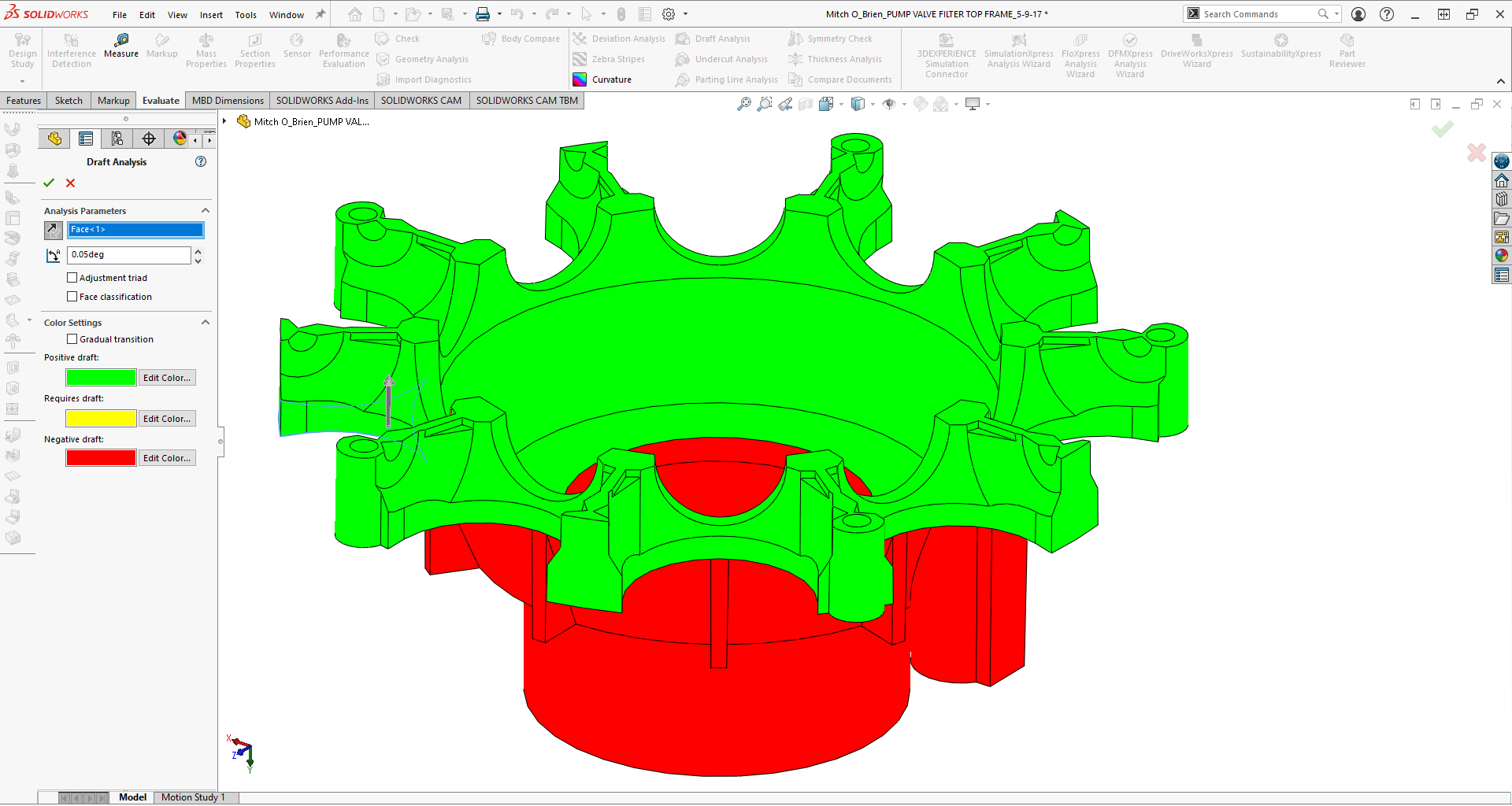

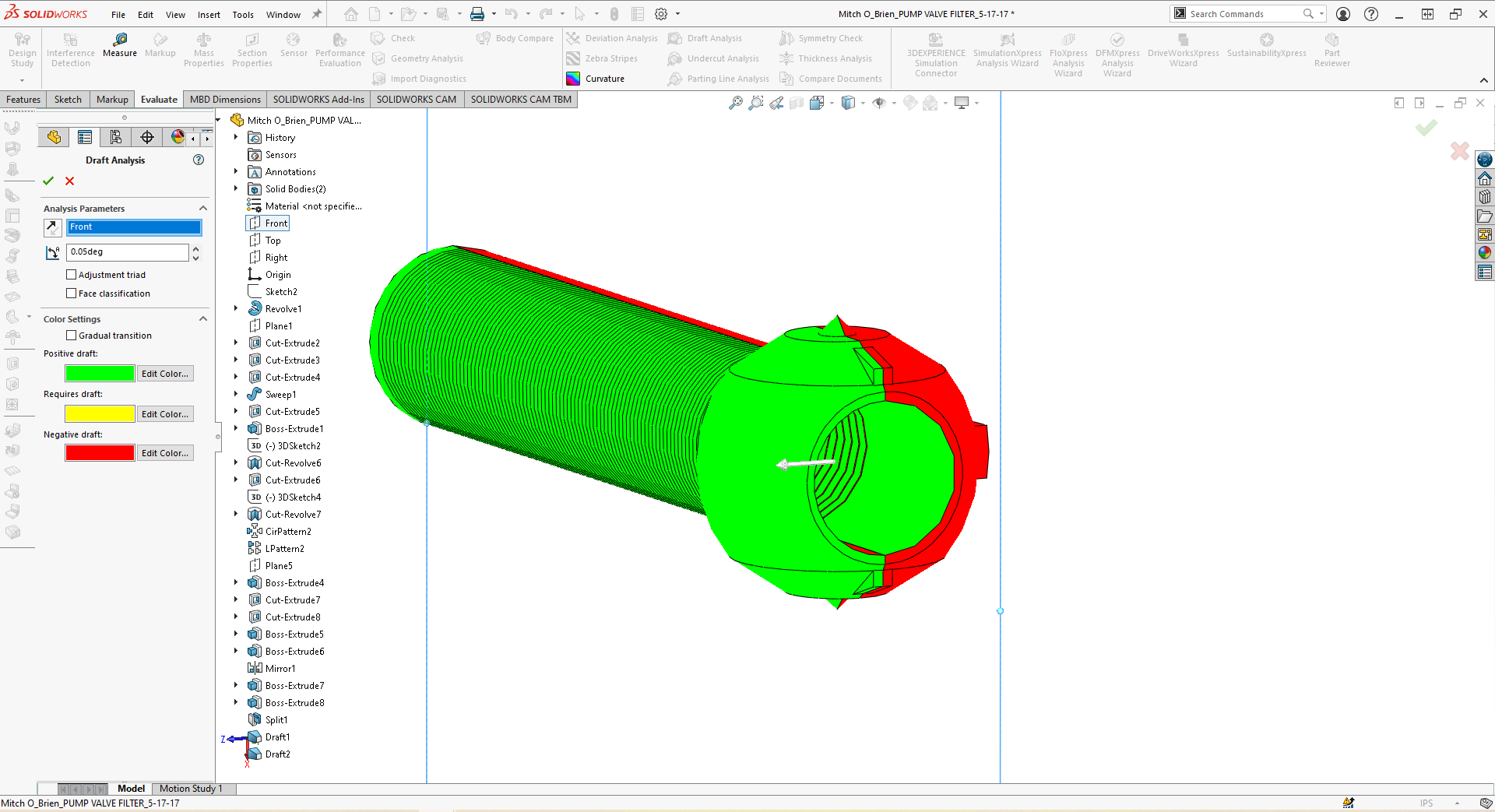

Thickness and draft analysis on check valve plunger case.

Deviation analysis on critical spacer edge for assembly and draft pull analysis.

Thickness analysis on both filter arm and main bottom filter housing body. For injection molding.

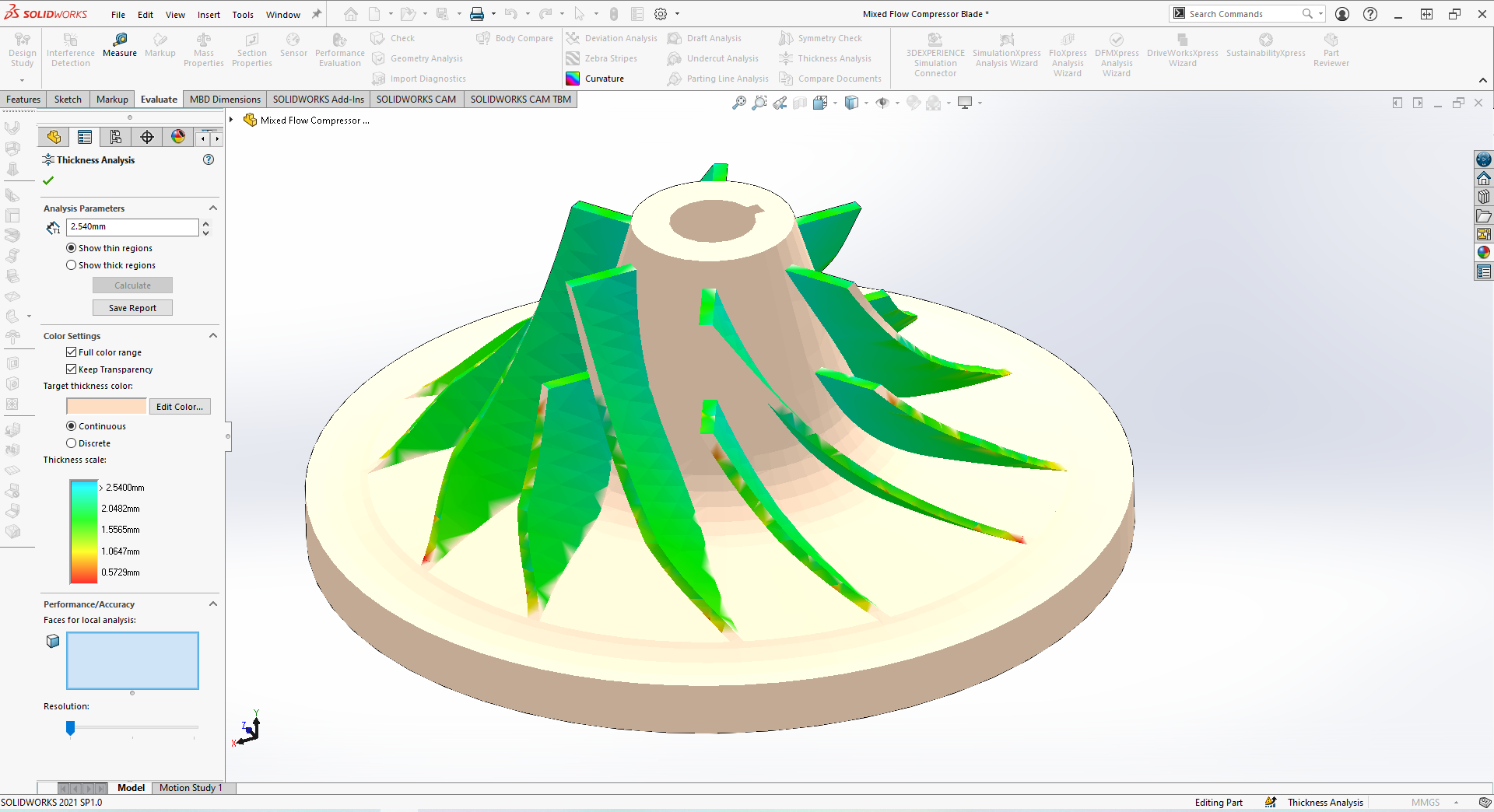

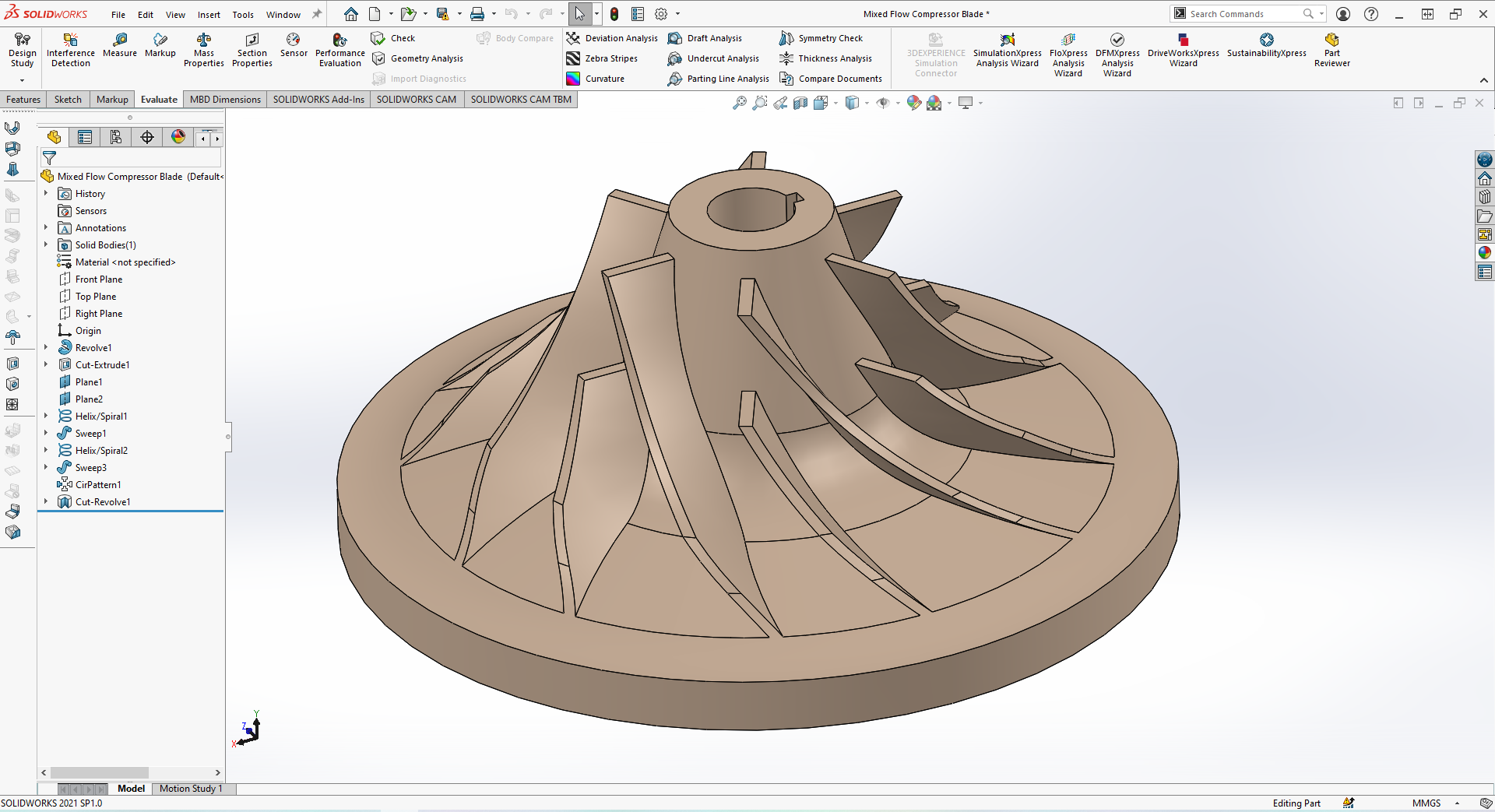

Modeled the mixed flow compressor then performed thickness analysis on blades.

Conducted Design for Manufacturability (DFM) assessments for injection molding. Established parting lines within components and modeled draft angles in both directions at a precise 0.5-degree angle.